The motor transmits power to the drum around which the steel wire rope is wound through a speed redu

Learn More

When the main motor is started, the power is transmitted from the rotor of the motor to the high-spe

Learn More

The JKMD mining hoist is a friction-type (multi-rope) mine hoist used for deep shaft lifting in coal

Learn More

When the main motor is started, the power is transmitted from the motor rotor to the high-speed shaf

Learn More

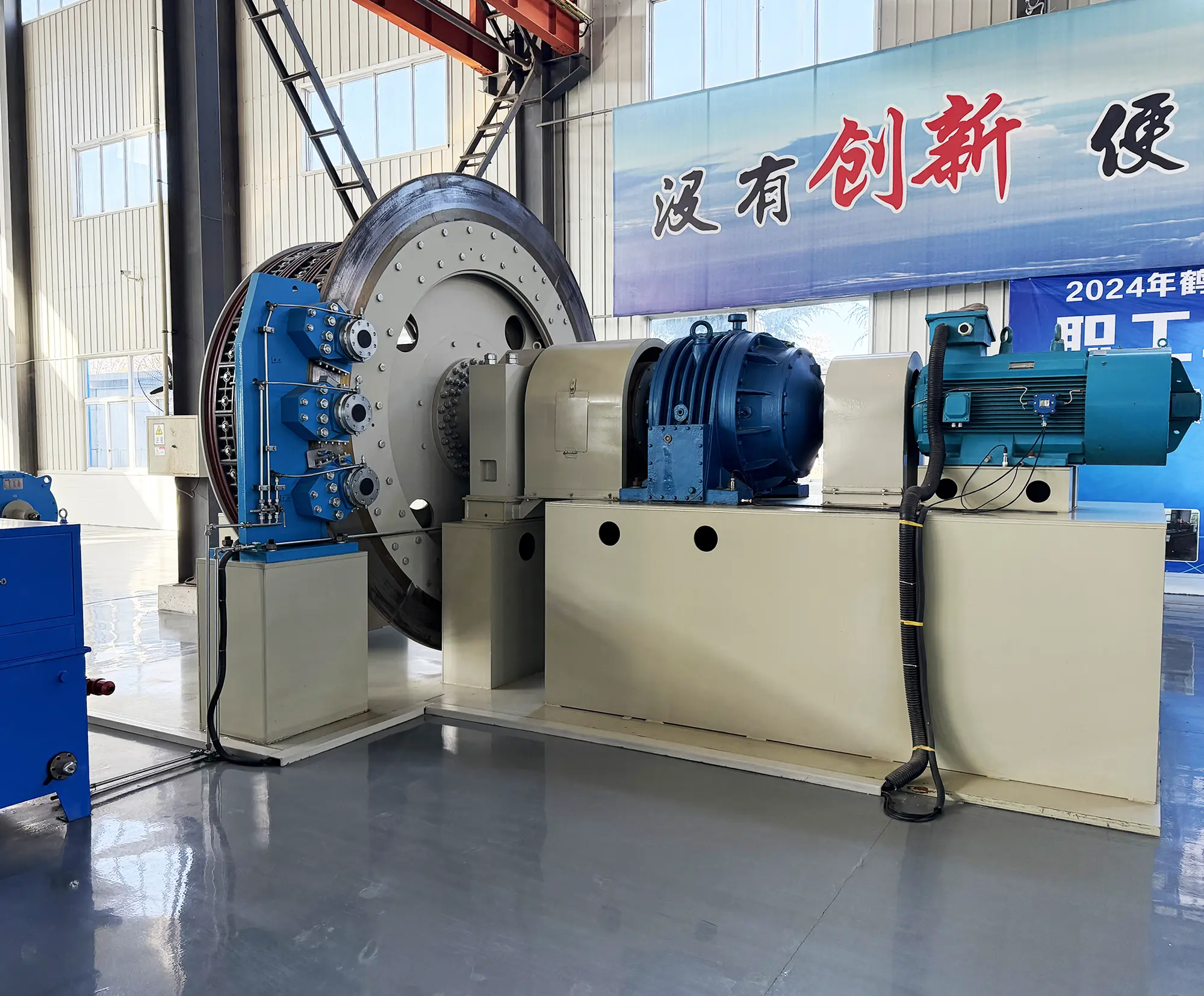

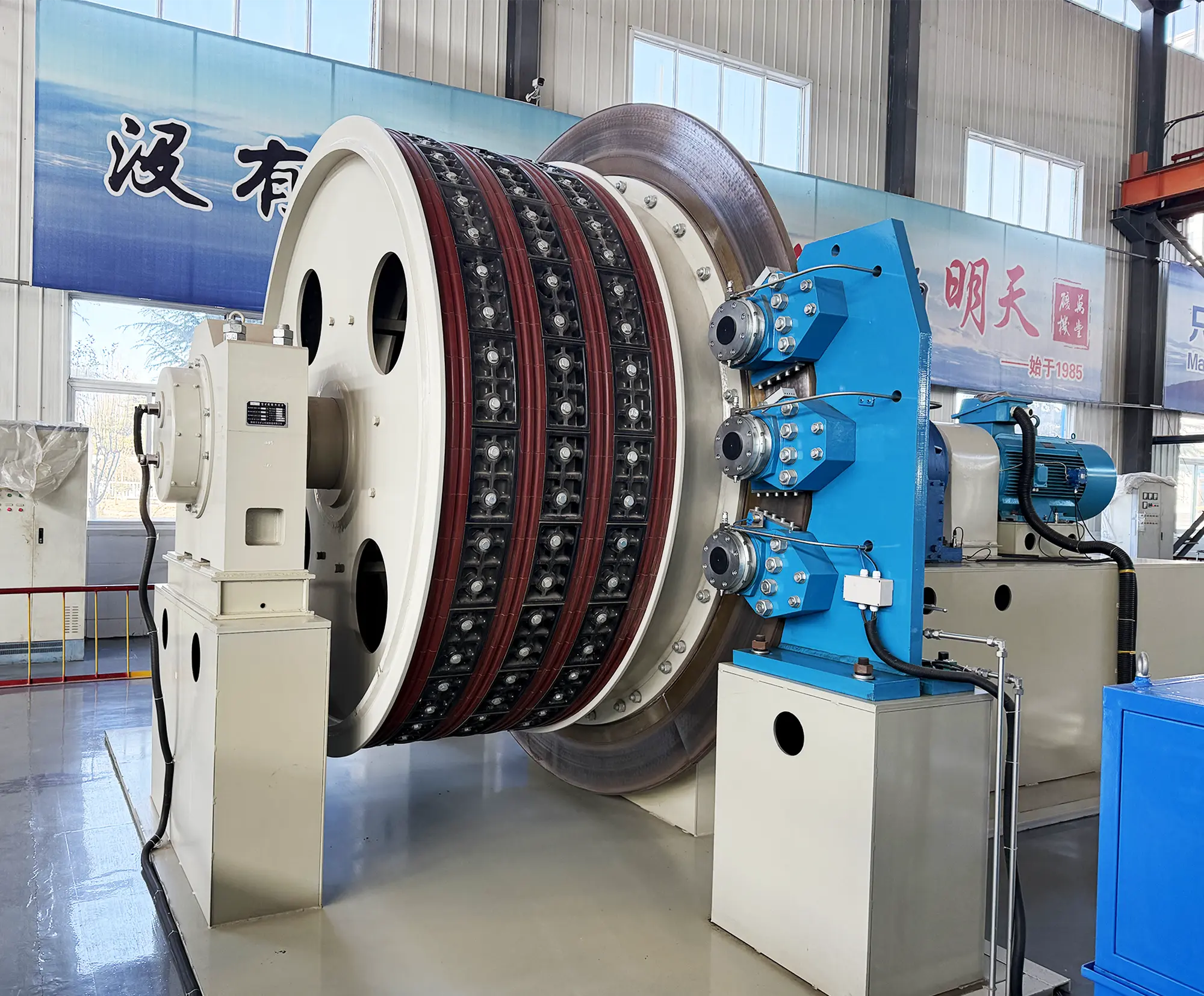

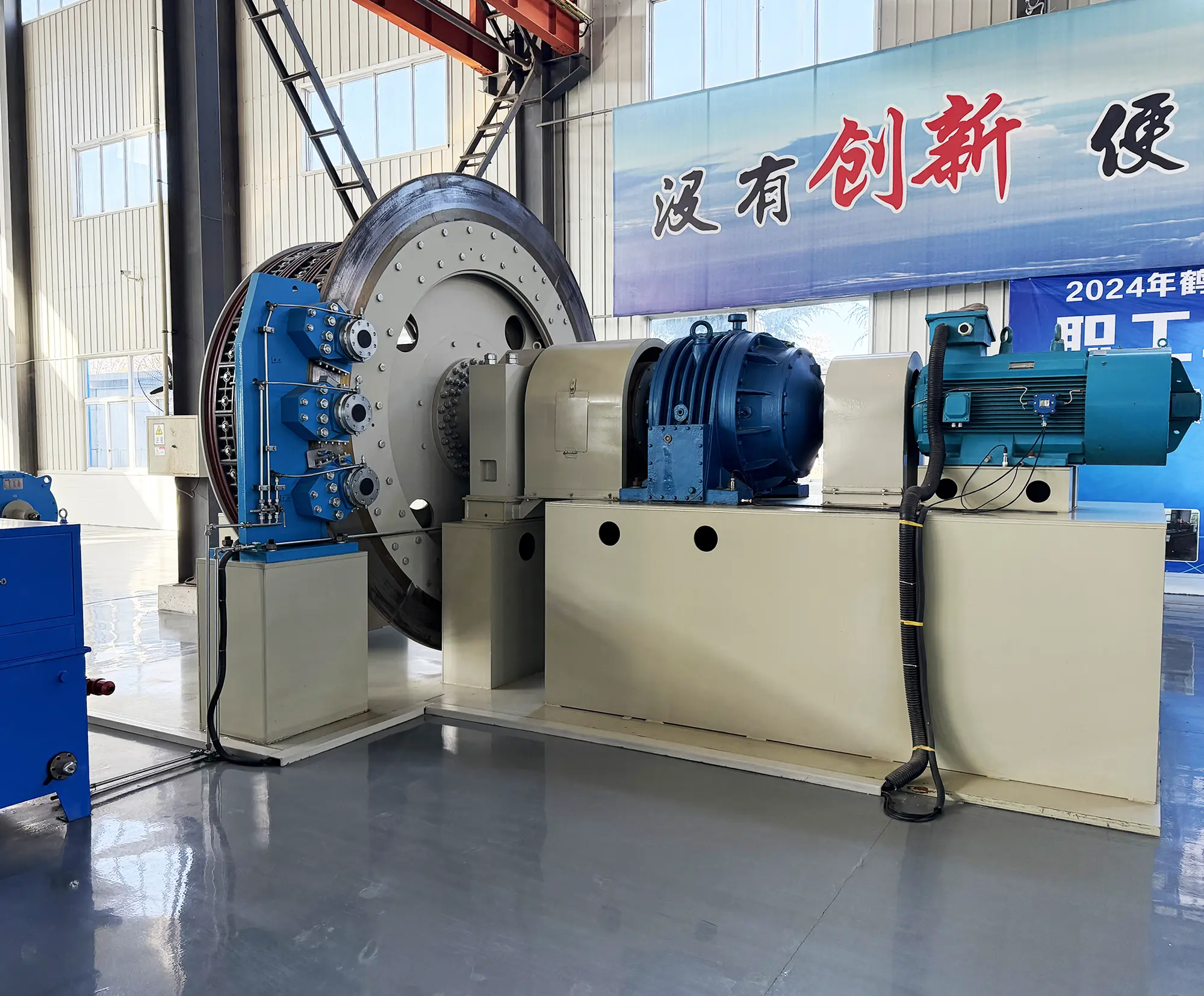

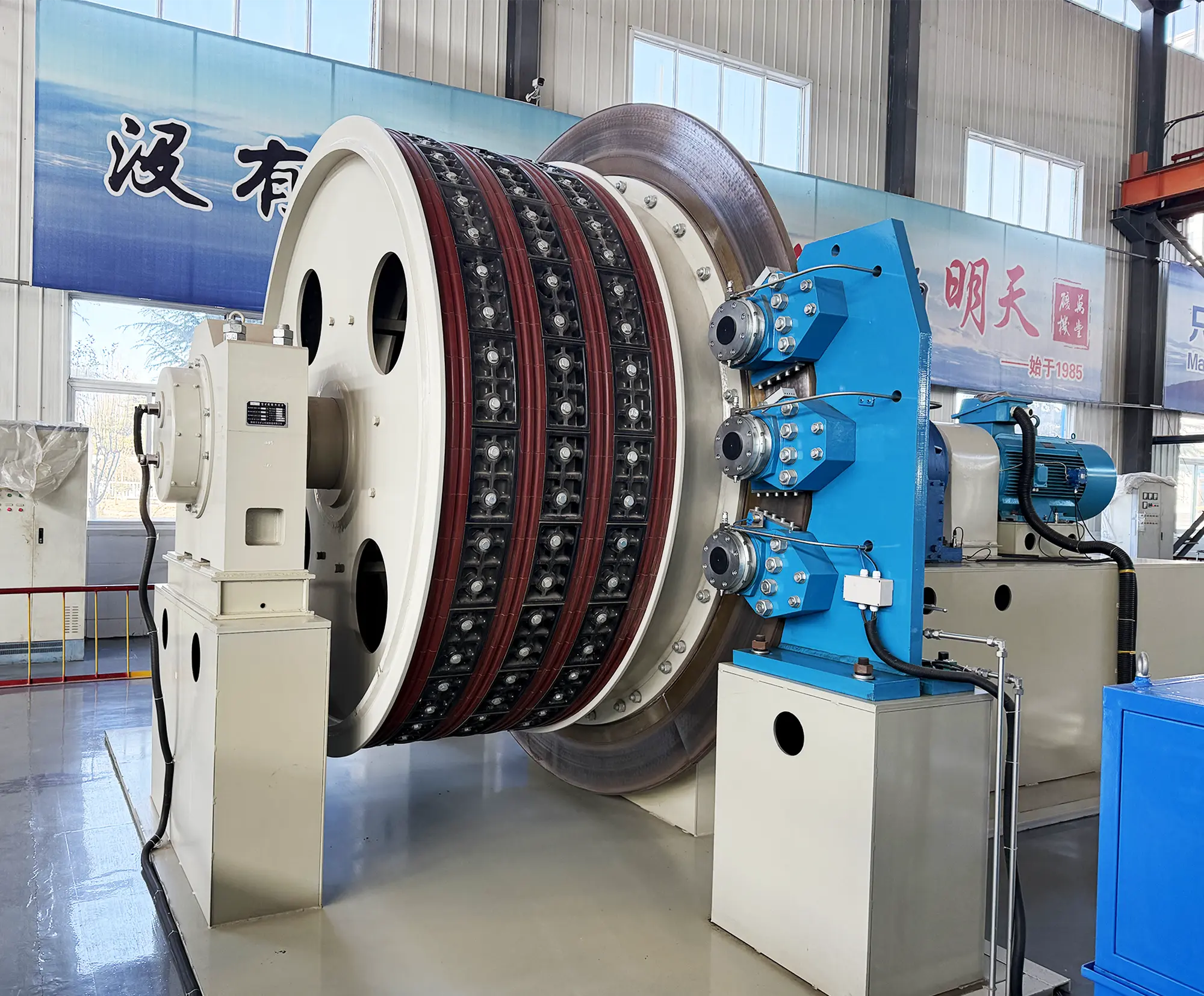

The multi-rope friction hoist is mainly composed of an electric motor, a reducer, a friction wheel, a braking system, a depth indicator, a speed measurement and limiting system, and a control system. It is driven by an AC or DC motor. When a low-speed motor is used, the reducer can be omitted. The motor is directly connected to the drum spindle, or the motor rotor is installed at the end of the drum spindle.

1. No emission, No pollution.

2. Automatic cable retraction.

3. Automatic adjustment of cable retraction force.

Multi-rope friction hoist

The multi-rope friction hoist is mainly composed of an electric motor, a reducer, a friction wheel, a braking system, a depth indicator, a speed measurement and limiting system, and a control system. It is driven by an AC or DC motor. When a low - speed motor is used, the reducer can be omitted. The motor is directly connected to the drum spindle, or the motor rotor is installed at the end of the drum spindle.

The braking system is an important device to ensure the safe operation of the hoist. In case of an emergency, the braking system should generate two - stage safety braking through a hydraulic system with adjustable braking torque to ensure that the hoist stops in time without excessive braking. For hoists driven by AC motors, the braking system should also have the performance of sensitive and adjustable braking torque to accurately control the running speed of the hoist near the stopping point.

The multi - rope friction hoist is divided into tower - type and surface - type according to the installation form. It is mainly used for lifting materials, personnel, and equipment in the shafts of coal mines, metal mines, and non - metal mines.

Since the electrical equipment supporting this product is non - explosion - proof, it cannot be used in places with flammable and explosive media such as gas.

The JKMD and JKM series of multi - rope friction hoists are designed and manufactured in accordance with the standards of AQ1036 - 2007 Safety Inspection Specification for Multi - rope Friction Hoists Used in Coal Mines, Q/YX007 - 2021 Multi - rope Friction Hoist, and GB/T10599 - 2010 Multi - rope Friction Hoist, as well as the Coal Mine Safety Regulations and GB16423 - 2020 Safety Regulations for Metal and Non - metal Mines.

Example 1: The product model of a tower - type multi - rope friction hoist with a friction wheel diameter of 3.5m, 4 steel ropes, a single motor with a reducer and resistance speed regulation is: JKM - 3.5*4Ⅰ.

Example 2: The product model of a tower - type multi - rope friction hoist with a friction wheel diameter of 3.25m, 4 steel ropes, two motors with a reducer and DC speed regulation is: JKM - 3.25*4ZⅡ.

Example 3: The product model of a surface - type multi - rope friction hoist with a friction wheel diameter of 4m, 4 steel ropes, a single motor without a reducer and frequency - conversion speed regulation is: JKMD - 4*4PⅢ.

Example 4: The product model of a surface - type multi - rope friction hoist with a friction wheel diameter of 4.5m, 4 steel ropes, two motors without a reducer and reluctance switch speed regulation is: JKDM - 4.5*4DⅣ.

| Model | Friction wheel diameter m | Friction coefficient | Steel wire rope | Max. lifting speed | Guide wheel diameter | Displacement weight of rotating part (excluding motor and guide wheel) | Displacement weight of guide wheel | Dimensions | |||||

| Max. static tension differential | Max. static tension | Max. diameter | Spacing | ||||||||||

| With guide wheel | Without guide wheel | with reducer | without reducer | ||||||||||

| kN | kN | mm | mm | m/s | m | t | t | m | |||||

| JKM-1.3×4 I | 1.3 | 0.25 | 30 | — | 105 | 16 | 200 | 5 | 16 | — | 2.86 | — | 5×3.2×1.83 |

| JKM-1.6×4 I | 1.6 | 40 | — | 150 | 20 | 8 | 4 | 6.4×3.6×2.1 | |||||

| JKM-1.85×4 I | 1.85 | 45/50 | 150 | 165 | 22 | 10 | 1.85 | 5.8 | 1.4 | 6.7×3.7×2.5 | |||

| JKM-2×4 I | 2 | 55 | 180 | 2 | 6.1 | 1.45 | 6×3.8×2.64 | ||||||

| JKM-2×5 I | 55 | 230 | 24 | 2 | 6.5 | 2.2 | 6.2×3.8×2.64 | ||||||

| JKM-2.25×2 I | 2.25 | 30 | 105 | 300 | 2.25 | 4.5 | 1.35 | 4.08×4.1×2.8 | |||||

| JKM-2.25×4 I | 65 | 215 | 200 | 6.2 | 1.5 | 6.3×4.2×2.8 | |||||||

| JKM-2.8×4 I | 2.8 | 100 | 335 | 30 | 250 | 15 | 2.8 | 9.5 | 2.65 | 7.5×4.8×3.6 | |||

| JKM-2.8× 4Ⅲ | 9.7 | 2.8 | 5×4.9×3.6 | ||||||||||

| JKM-2.8×6Ⅰ | 160 | 520 | 11.6 | 3.7 | 8.5×4.9×3.4 | ||||||||

| JKM-2.8× 6Ⅲ | 12 | 6×4.9×3.4 | |||||||||||

| JKM-3×4Ⅰ | 3 | 140 | 450 | 32 | 300 | 3 | 15.5 | 4.5 | 8.6×4.95×3.7 | ||||

| JKM-3×4Ⅰ | 12.5 | 4.8 | 5×5.1×3.7 | ||||||||||

| JKM-3.25×4Ⅰ | 3.25 | 160 | 520 | 36 | 3.25 | 13.8 | 5 | 8.5×5.2×4.1 | |||||

| JKM-3.25×4Ⅲ | 12.5 | 5.3×5.2×4.1 | |||||||||||

| JKM-3.5×4Ⅰ | 3.5 | 180 | 570 | 38 | 3.5 | 15.2 | 5.2 | 8.5×5.4×4.2 | |||||

| JKM-3.5× 4Ⅲ | 14.2 | 5.5×5.4×4.2 | |||||||||||

| JKM-3.5× 6Ⅲ | 270 | 860 | — | 21.1 | 6.5 | 7×5.4×4.2 | |||||||

| JKM-4×4Ⅰ | 4 | 770 | 44 | 4 | 23.5 | 5.6 | 10.5×4.7×4.7 | ||||||

| JKM-4× 4Ⅲ | 20.2 | 5.8×4.7×4.7 | |||||||||||

| JKM-4× 6Ⅲ | 340 | 1200 | 27.5 | 7.5 | 6.5×4.7×4.7 | ||||||||

| JKM-4.5× 4Ⅲ | 4.5 | 980 | 50 | 4.5 | 28.1 | 7.7 | 6.1×5.3×5.3 | ||||||

| JKM-4.5×6Ⅲ | 440 | 1450 | 33.3 | 11.9 | 6.5×5.3×5.3 | ||||||||

| JKM-4.5×6Ⅳ | 34.1 | 8.6×5.3×5.3 | |||||||||||

| JKM-4.6× 6Ⅲ | 4.6 | 1500 | 52 | 4.6 | 35.2 | 13 | 6.5×5.4×5.4 | ||||||

| JKM-4.6×6Ⅳ | 36 | 8.6×5.4×5.4 | |||||||||||

| JKM-5× 4Ⅲ | 5 | 400 | 1500 | 54 | 5 | 30.5 | 14.1 | 6.1×5.8×5.8 | |||||

| JKM-5× 6Ⅲ | 500 | 1650 | 38.1 | 16.2 | 6.5×5.8×5.8 | ||||||||

| JKM-5×6Ⅳ | 40.1 | 8.6×5.8×5.8 | |||||||||||

| JKM-5.5× 4Ⅲ | 5.5 | 1500 | 60 | 350 | 5.5 | 40 | 15.2 | 7.2×6.3×6.3 | |||||

| JKM-5.5×4Ⅳ | 42.5 | 9.4×6.3×6.3 | |||||||||||

| JKM-5.5× 6Ⅲ | 600 | 2000 | 50.5 | 18.6 | 8.2×6.3×6.3 | ||||||||

| JKM-5.5×6Ⅳ | 54 | 10.5×6.3×6.3 | |||||||||||